Ensuring Safe and Quality Dairy Products

Pasteurization is critical for milk and dairy safety—but it’s not always straightforward. Incomplete pathogen kill is a real risk. Pasteurization must eliminate harmful bacteria like Salmonella, Listeria, and E. coli. If the temperature or exposure time is off, some bacteria can survive, creating serious health hazards for consumers.

Improper pasteurization also affects product quality:

- Off-flavors or spoilage due to protein and fat changes

- Shortened shelf life from bacterial growth

- Regulatory violations, batch wastage, and loss of consumer trust

For operators, this can mean stressful shifts and constant vigilance. Supervisors worry about audits and batch verification, while decision-makers focus on maintaining compliance, brand reputation, and consistent product quality.

Every batch that leaves your plant carries responsibility. Operators often feel the pressure of getting it right, knowing any mistake can compromise safety. Supervisors struggle to verify every detail in time. Managers and top executives are tasked with ensuring the entire operation meets regulatory standards while avoiding wastage or recalls.

It’s not just about following a process—it’s about peace of mind, consumer safety, and trust in your brand.

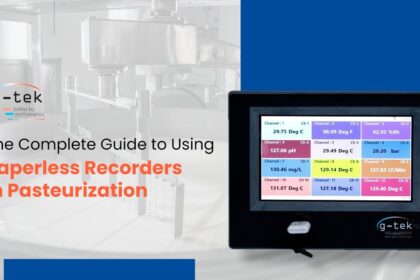

This is where paperless recorders make a difference. These devices continuously track temperature and time and automatically store the data. With options to mark the start and stop time of each batch, operators no longer have to second-guess the process.

Integration is seamless, dashboards are intuitive, and remote monitoring ensures you can access live data from anywhere — whether checking batch performance, receiving alerts, or verifying compliance in real time, oversight becomes effortless and proactive.

How Paperless Recorders Solve the Problem

Paperless recorders turn pasteurization into a controlled, traceable process:

- Operators: Focus on plant operations confidently, knowing every batch is monitored automatically

- Supervisors: Receive instant alerts and can monitor multiple lines remotely, ensuring deviations are addressed immediately

- Managers: Access accurate batch reports and track plant performance from anywhere, improving decision-making efficiency

- Top Management: Maintain brand trust, operational efficiency, and consistent product quality across plants, even remotely

Key Features:

- Continuous temperature/pressure and time tracking

- Start/stop batch options for precise monitoring

- Automated alerts and dashboards for decision-making

- Real-time visibility, anywhere

- Tamper-proof records for regulatory compliance

With paperless recorders and remote monitoring, you prevent health hazards, compromised quality, regulatory issues, and wastage—all while simplifying compliance checks and maintaining consumer trust.

Ensure Compliance Every Time

If pasteurization compliance is a priority for your dairy operation, paperless recorders are your solution. Protect your products, maintain quality, and stay fully compliant with precise monitoring.

Contact G-Tek Corporation to schedule a 1-on-1 session with our expert to see how paperless recorders and remote monitoring can fit your plant, simplify workflow, and give your team confidence and peace of mind.